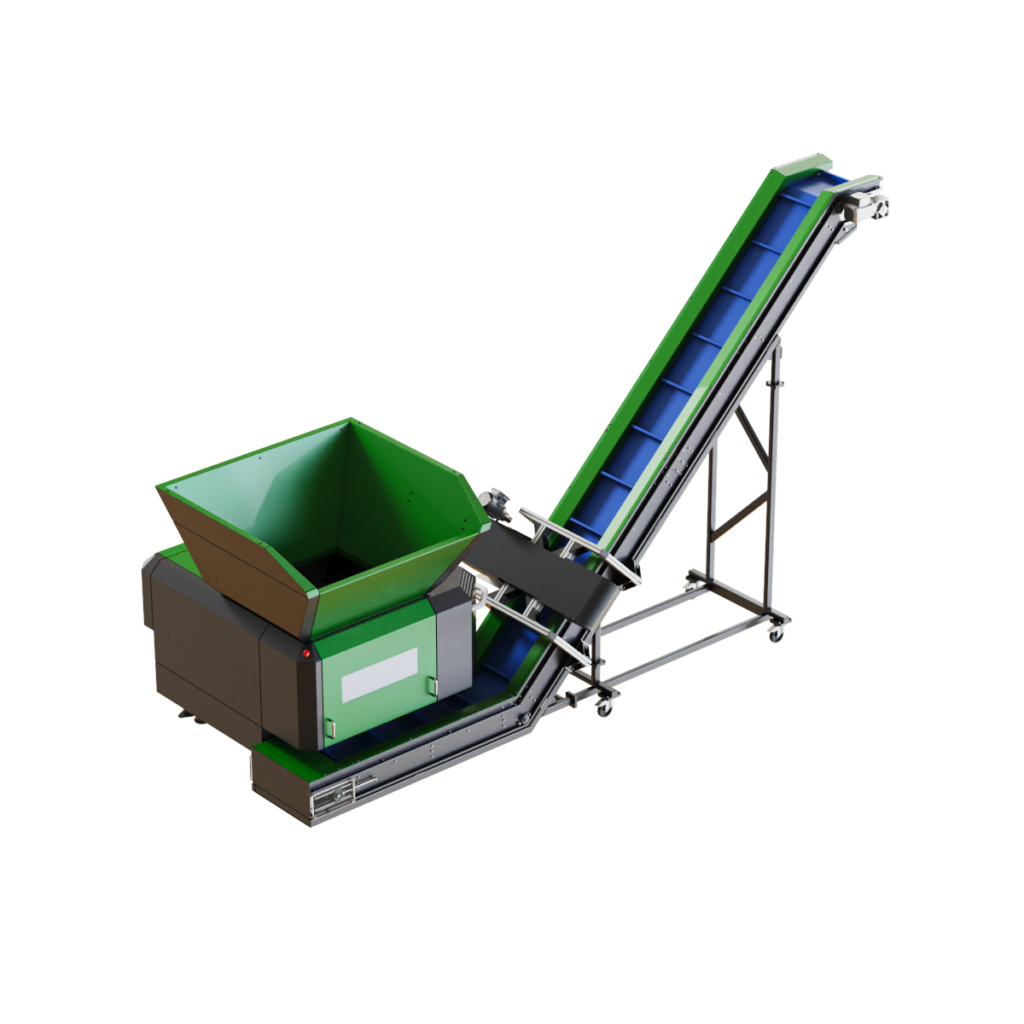

The Robust Reuser RZC conveyor belt makes no compromises. Designed for those who know that quality lasts not only a few months, but decades.

The sturdy construction will withstand the challenges of time, flawlessly manage the transport of wood chips, plastic residues and many other materials, and provide you with exceptional flexibility in the premises.

| Drive (V) | Electricity 400 |

| Required power (kW) | 0.25 |

| Maximum width of materials on the belt (mm) | 340 |

| Maximum weight of materials on the belt (kg) | 50 |

| Temperature range of transported product (C°) | 0–60 |

| Belt conveyor operating temperature range (C°) | 0–40 |

| Dimensions H/W/D (mm) | 3357/1021/5287 |

| Material ejection height (mm) | 3357 |

| Transport rubber width (mm) | 381 |

| Outer width of conveyor belt (mm) | 645 |

| Magnetic separator upgrade | optional |

| Compatible with models | SD 700, SD 900, SD 900XL, HD 1500 “Monster”, QD |

| Drive (V) | Electricity 400 |

| Required power (kW) | 0.25 |

| Maximum width of materials on the belt (mm) | 340 |

| Maximum weight of materials on the belt (kg) | 50 |

| Temperature range of transported product (C°) | 0–60 |

| Belt conveyor operating temperature range (C°) | 0–40 |

| Dimensions H/W/D (mm) | |

| Material ejection height (mm) | 3357 |

| Transport rubber width (mm) | 381 |

| Outer width of conveyor belt (mm) | 645 |

| Magnetic separator upgrade | optional |

| Compatible with models | ID 1400 |

Robust Reuser RZC 350 & RZC 350 ID conveyor belt is intended for users who would like to transport the crushed material efficiently and qualitatively from the crushing machine. It is used for the output of crushed material such as wood, plastic, paper, cardboard, aluminum and perfectly matches the crusher of the Robust Reuser SD 700, SD 900, SD 900XL series and HD 1500 “Monster“ models. Since on wheels, it is easy to operate. The conveyor belt can be upgraded with an above-belt magnetic separator and a magnetic separator in the drive roller.

Sustainable development enables the transition to a greener way of life, while at the same time focusing on the issue of depletion of natural resources and environmental pollution. With its sustainability strategy, the Robust brand strongly advocates for the changes necessary for the decarbonization of organizations and wider society.

We are the Robust people who make the future greener. Committed, dedicated, uncompromising, we fight with our users for a more beautiful and better tomorrow. Our persistence and the rebellious spirit is pronounced, but we are calm and prudent. We radiate passion. We transform challenges into solutions.

All or nothing. There be no road between. The value of our brand depends on how much and what uniqueness we can offer you, the users. The Robust brand products have only one goal – to turn your challenge into a solution.

The mission of our forestry equipment and recycling machinery is to exceed your expectations by achieving high productivity, optimization of operating costs and maximum safety .

“More is more!” Our high development orientation is confirmed by six patented solutions that contribute to greater productivity, they maintain toughness and longer lifetime of the machine.

“Save where the result will be visible!” By implementing state-of-the-art software and a selective choice of built-in components with above-average safety and efficiency factors, we – for our costumers – optimize operating costs and guarantee continuous multi-shift operation of forestry machines, crushers and other recycling equipment under the most demanding conditions.

“Safety first!” The safety of you or of your employees is crucial. All our products are manufactured in accordance with safety and health EU guidelines.

Having a technical challenge? We are here solely for you. One of the key features of the Robust brand is expert technical team of consultants here to assist you. Your satisfaction is our guarantee of success.